Max Machining

A Comprehensive Resource for CNC Turning with Advanced Capabilities

Expertise and Experience

Skilled Professionals: Max Machining boasts a team of highly experienced engineers and technicians specializing in CNC turning.

Deep Understanding: With years of experience, the team possesses an in-depth understanding of CNC turning processes and techniques.

Continuous Development: Staff undergo regular training to stay updated with the latest advancements in CNC turning technology and methodologies.

State-of-the-Art Facility

Advanced Equipment: Max Machining's facility is equipped with state-of-the-art CNC turning machines featuring advanced capabilities for precision and efficiency.

Bar Feeding for 3" Round Stock: The facility is equipped with bar feeding systems capable of handling 3" round stock, allowing for efficient and uninterrupted production.

Live Tooling: Max Machining's CNC turning machines feature live tooling capabilities, enabling the milling of offset features directly on the turned parts, reducing the need for additional machining operations.

24/7 Operation: Max Machining operates round the clock, ensuring continuous production and quick turnaround times for client projects.

Versatility in Materials

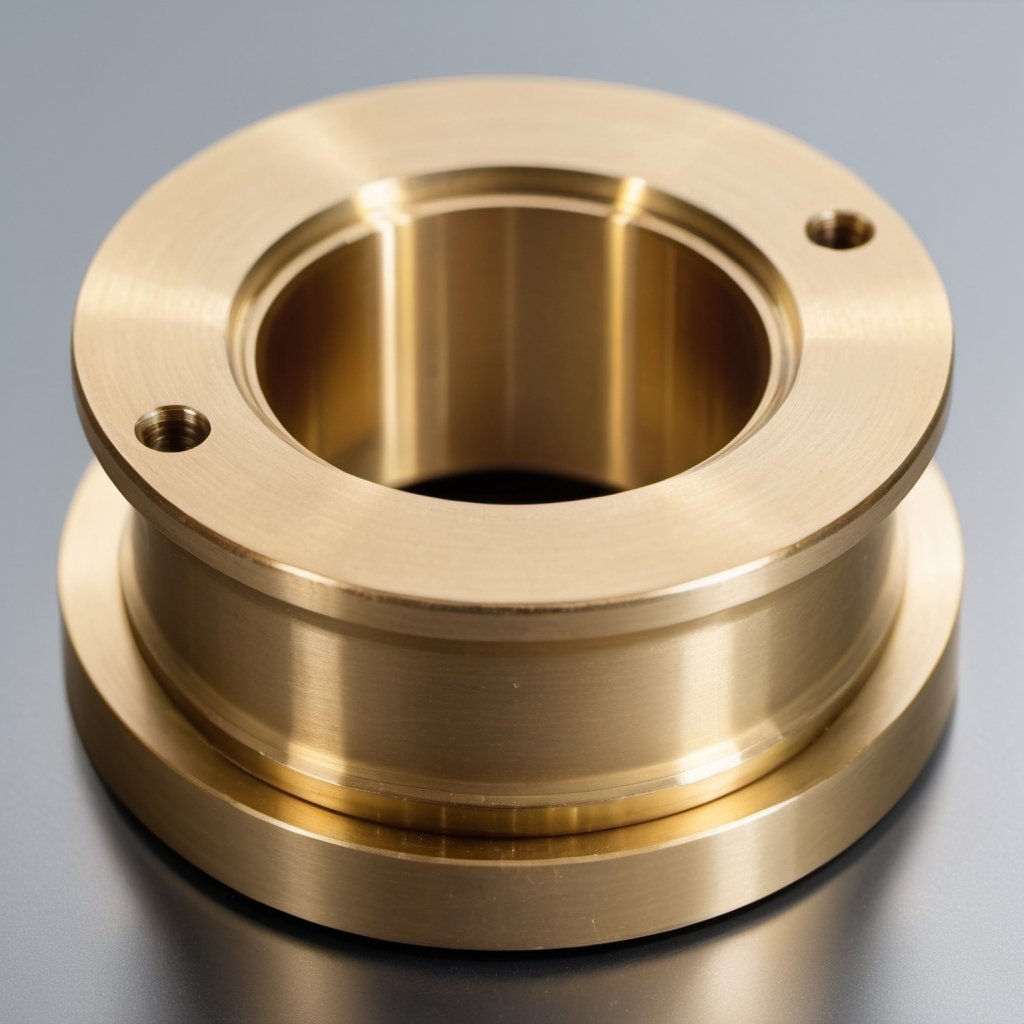

Material Compatibility: Max Machining can work with a wide range of materials suitable for CNC turning, including metals (such as stainless steel, brass, and copper), plastics, and more.

Material Expertise: The team possesses extensive knowledge of different materials' properties, enabling them to optimize CNC turning processes accordingly.

Customization and Prototyping

Tailored Solutions: Max Machining offers customizable CNC turning services to meet specific client requirements, from initial design to final production.

Rapid Prototyping: Clients benefit from quick turnaround times for prototypes, facilitated by efficient production processes and 24/7 operation.

Efficiency and Timeliness

Prompt Delivery: Max Machining prioritizes efficiency, delivering projects within agreed-upon timelines without compromising on quality.

Streamlined Processes: The company employs efficient workflows and project management systems to minimize lead times and enhance productivity.

Cost-Effectiveness

Competitive Pricing: Max Machining provides competitive rates for CNC turning services, ensuring clients receive value for their investment.

Optimization Strategies: The team implements cost-saving measures and optimization techniques to minimize production expenses while maintaining quality standards.

Customer Service Excellence

Responsive Support: Max Machining is committed to delivering excellent customer service, offering timely responses to inquiries and addressing any concerns promptly.

Collaborative Approach: The team works closely with clients throughout the CNC turning process, fostering collaboration and ensuring alignment with their needs and expectations.

Industry Compliance and Standards

Regulatory Adherence: Max Machining adheres to industry regulations and standards, ensuring all products meet or exceed quality and safety requirements.

Certification: The company may hold relevant certifications for CNC turning processes, demonstrating its commitment to excellence and compliance.

Max Machining stands out as a premier resource for CNC turning, leveraging expertise, advanced facility with specialized capabilities, including bar feeding for 3" round stock, live tooling for milling offset features, 24/7 operation, and exceptional customer service to deliver superior results for clients across diverse industries.